Mask production

line, anti corona virus respirator.

Respirator

maker.

A complete set of equipment for making anti-virus

respirator facemask with PP chip as raw material.

www.chinafiber.com/respiratormask

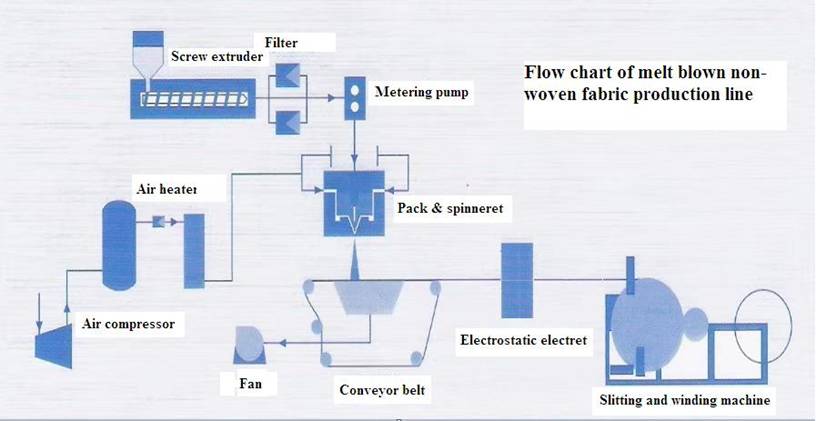

Spinning section

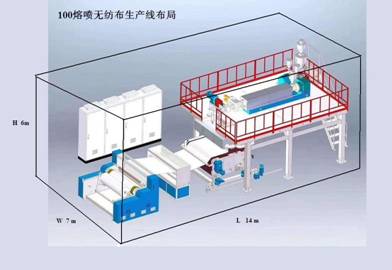

Capacity 0.3 Ton/day, 24 hours work

raw material Polypropylene chip.

Product melt blown non-woven.

Width

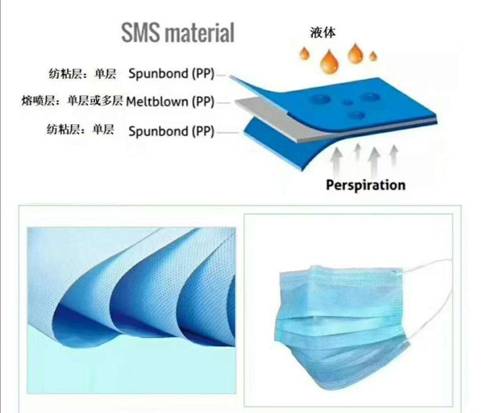

Melt blown non-woven fabric is the most important filter material in

mask.

Mask making

section

One unit: Capacity 100 pcs / min, about

If you want these machines to work only 12 hours a day, you need to

order 3 units.

In order to make

a perfect respirator mask, you also need to prepare the following materials:

1. The belt hanging on the ear, made of spandex, has

elasticity. 2. Clamp the small metal strip on the bridge of nose. 3. Melt blown

non-woven fabric as filter layer in the middle, There

is a waterproof and breathable layer outside, and the inner layer is a sweat

wicking layer compatible with the skin.

ChinaFiber XinLun

Rm.208,

Kai-Tai Mansion, Building No.5, Yard No.3, Yan-Jing-Li Mid-Str., Chao-Yang

District, Beijing 100025 China.

Tel: +86 10 84042763,

Fax: +86 10 84035346,

www.chinafiber.com E-Mail: sales@chinafiber.com

www.chinafiber.com/respiratormask